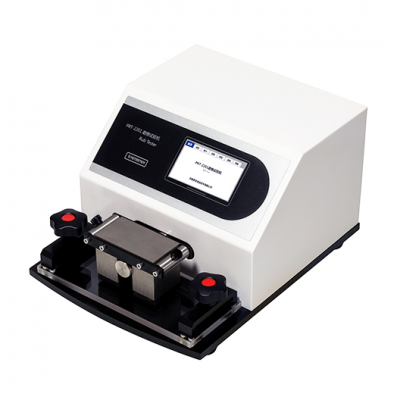

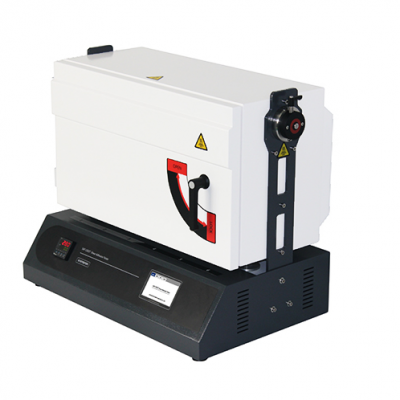

Application

| GTR 736 is based on the differential pressure method, and is professionally applicable to the determination of gas transmission rate as well as solubility coefficient, diffusion coefficient and permeability coefficient of plastic films, laminated films, high barrier materials, sheeting, metal foils, rubber, tires and permeable membranes. |

Features

| Vacuum differential pressure method Own technology One specimen test Computer control One-button test, test automatically through whole process High accuracy vacuum sensors embedded in Chamber temperature sensor embedded in Environment temperature and humidity sensor inside Permeability coefficient ,solubility coefficient and diffusion coefficient test Chamber with water bath temperature control technology (optional) Unit based on embedded system,24bit Δ-Σ AD Multiple test modes optional Data curves display Traceable reference film calibration Supports DSM system (DSM, lab data management system) |

Technical

| Test range | 0.05-160,000 cm3/m2·24h·0.1MPa (Standard) |

| Resolution | 0.001cm3/m2·24h·0.1MPa |

| Samples | one piece |

| Vacuum accuracy | 0.1Pa |

| Temperature range | 5C-95C (With temperature controller) |

| Temperature accuracy | ±0.1C |

| Sample thickness | less 3mm |

| Sample size | >=150mm * 94mm |

| Test area | 48cm2 |

| Test gas | O2, N2, CO2, He, etc (Flammable or toxic gases test available: H2, CH4, H2S, C2H2,C2H4 etc, must be announced in advance) |

| Differential pressure | -0.1MPa-0.1MPa; 1.0MPa, 4.0MPa(optional) |

| Gas interface | Ф8mm |

| Dimension | 330mm(L) * 600mm(W) * 330mm(H) |

| Power supply | AC 220V 50Hz |

| Net wt | 28kg |

Standard

| ASTM D1434, ISO 15105-1,ISO 2556,GB/T 1038-2000,JIS 7126-1,YBB 00082003 |

Configuration

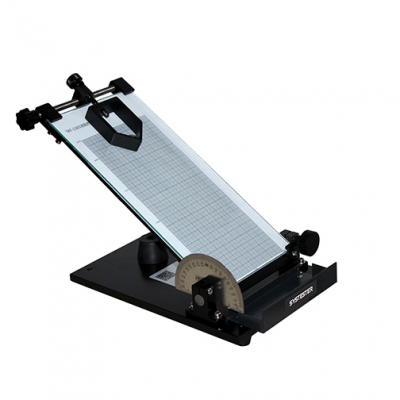

Delivery: Main unit, computer, G-TRANS software, vacuum pump, tank regulator, PCIE card, communication cable, sample cutter, vacuum grease. Optional: Temperature controller, reference film, vacuum grease, sample cutter, DSM system. Note: Specifications are subject to change without prior notice |

English

English